Farming is a labor-intensive job, and your machinery plays a crucial role in ensuring everything runs smoothly. Regular maintenance of farm equipment is not only essential for keeping your machinery in optimal condition but also for avoiding unexpected breakdowns during crucial planting or harvesting seasons. Following a detailed farm equipment maintenance checklistcan help extend the life of your machines, prevent costly repairs, and boost overall productivity.

In this blog, we will outline important farm machinery maintenance tips, covering everything from preventive maintenance for farm equipment to best practices for prolonging equipment lifespan. Whether you have tractors, seeders, or combines, this guide will provide practical tips to ensure your agricultural machinery stays in top shape.

Why Farm Equipment Maintenance is Important

Before diving into the checklist, let's first discuss why maintaining your farm equipment is crucial. Agricultural machinery is a significant investment, and proper upkeep can significantly extend its lifespan. Regular maintenance helps to:

- Reduce Downtime: Unplanned equipment failure can result in delays that may disrupt your entire farming operation.

- Lower Repair Costs:Preventive maintenance can help catch minor issues before they become major (and more expensive) problems.

- Increase Efficiency:Well-maintained machines perform better, leading to more efficient farming operations and higher yields.

- Ensure Safety:Regular maintenance checks ensure that your machinery operates safely, reducing the risk of accidents.

By following a comprehensive farm equipment maintenance checklist, you can ensure that your machines last longer and operate at their best. Let’s get into the key steps for maintaining your machinery.

- Inspect Your Equipment Regularly

The first and most important step in any farm equipment maintenance checklist is to inspect your machinery regularly. A quick visual inspection before and after use can help you catch issues early on.

What to Look For During Inspections:

- Fluid Leaks:Check for any signs of oil, fuel, or hydraulic fluid leaks. These could indicate damaged seals or hoses that need to be replaced.

- Tire Pressure:Ensure that tires are inflated to the correct pressure. Improper tire pressure can affect traction and fuel efficiency.

- Cracks or Wear:Look for cracks in welds, worn-out belts, or frayed wires. These small issues can worsen over time and lead to equipment failure if not addressed promptly.

Pro Tip:

Consider setting up a daily or weekly inspection schedule depending on the frequency of machine use. Keeping a logbook to record any observed issues or repairs can also help you stay on top of maintenance.

- Change Oil and Fluids Regularly

Just like cars, farm machinery requires regular oil changes to function properly. Oil and other fluids such as hydraulic fluid, coolant, and transmission fluid are essential for keeping your machinery's components running smoothly.

Key Points for Fluid Maintenance:

- Engine Oil: Change the oil and oil filter at recommended intervals based on your equipment's manual. Fresh oil ensures that the engine parts stay lubricated and reduces wear.

- Hydraulic Fluid: Ensure that hydraulic fluid levels are adequate and that the fluid is clean. Dirty or low hydraulic fluid can lead to malfunctioning of hydraulic systems.

- Coolant:Keep an eye on your machine’s coolant levels, especially during high-temperature seasons. Low coolant levels can cause your engine to overheat, leading to expensive repairs.

Pro Tip:

Always use the manufacturer-recommended type of oil and fluids for your machinery. Using the wrong type can cause damage and void warranties.

- Keep Filters Clean

Filters play a critical role in protecting your machinery’s engine and other components from dust, dirt, and debris. A clogged filter can cause poor engine performance, reduce fuel efficiency, and even result in engine failure.

### Types of Filters to Maintain:

- Air Filters: Dust and debris can clog the air intake system, reducing the efficiency of your engine. Clean or replace the air filters regularly to ensure proper airflow.

- Oil Filters: Always replace the oil filter when changing the engine oil to keep the oil clean and free of contaminants.

- Fuel Filters: A clogged fuel filter can restrict fuel flow, causing your engine to work harder. Regularly inspect and replace fuel filters as necessary.

Pro Tip:

Check filters more frequently if your machinery operates in dusty or dirty environments, such as plowing fields or harvesting crops.

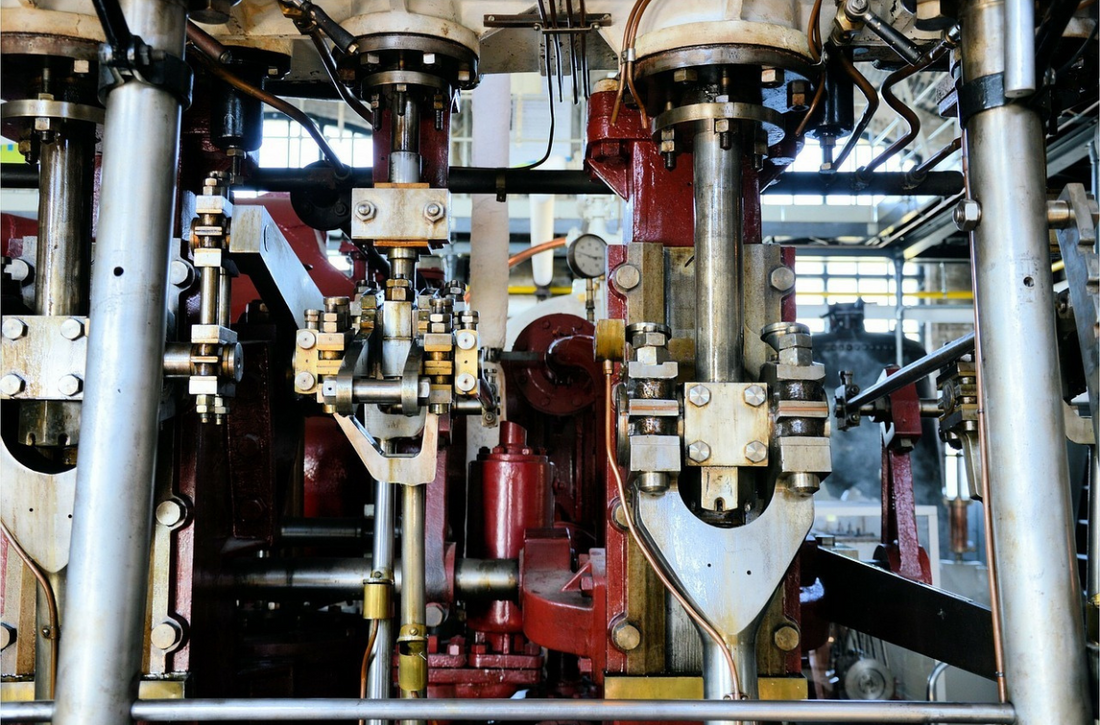

- Lubricate Moving Parts

Farming machinery has numerous moving parts, and keeping them properly lubricated is essential to avoid friction, wear, and eventual failure. Prolonging equipment lifespanoften boils down to ensuring that all gears, bearings, and other moving components are adequately greased.

Where to Apply Lubrication:

- Joints and Bearings:Keep these areas well-lubricated to prevent wear and tear from friction.

-Hydraulic Cylinders:Regularly check the hydraulic cylinders for smooth operation and apply grease as needed.

- Chains and Belts:Make sure that chains and belts are lubricated and aligned correctly to prevent slippage or snapping.

Pro Tip:

Use the correct type of lubricant for each part of your machine as recommended by the manufacturer. Too much grease can attract dirt, while too little can lead to wear.

- Check Electrical Systems

Your farm machinery’s electrical system is just as important as its mechanical components. A well-maintained electrical system ensures that your equipment starts reliably and functions properly.

Key Areas to Inspect:

- Battery:Check the battery's voltage regularly and inspect for corrosion on the terminals. A weak battery can lead to unreliable starting or cause electronic systems to malfunction.

- Wiring and Connections:Inspect wiring for signs of wear, corrosion, or loose connections. Damaged wiring can cause short circuits or fire hazards.

- Lights and Signals:Ensure that all lights, signals, and warning systems are functioning properly, especially if you use machinery on public roads or during nighttime operations.

Pro Tip:

Keep spare fuses and bulbs on hand to quickly replace any electrical components that may fail while you're in the middle of an operation.

- Store Equipment Properly

Proper storage can significantly impact the lifespan of your farming equipment. Leaving machinery exposed to the elements, especially during off-seasons, can lead to rust, corrosion, and other forms of deterioration.

Tips for Proper Equipment Storage:

- Indoor StorageWhenever possible, store your machinery in a clean, dry shed or garage to protect it from rain, snow, and extreme temperatures.

- Cover Equipment: If indoor storage is not an option, cover your machines with tarps to keep out moisture and debris.

- Winterizing:For seasonal equipment, winterize your machinery by draining fluids, removing batteries, and adding fuel stabilizer to prevent issues during long-term storage.

Pro Tip:

Ensure that your equipment is clean and dry before storing it to prevent the build-up of dirt and rust.

- Follow the Manufacturer's Maintenance Schedule

Every piece of farm equipment comes with a manufacturer-recommended maintenance schedule. Following this schedule is key to ensuring your machinery’s optimal performance. Whether it’s a routine oil change, filter replacement, or inspecting certain parts after a specific number of hours in operation, sticking to this guide will help you avoid major repairs down the line.

Pro Tip:

Keep a detailed record of all maintenance tasks performed, including dates and any repairs done. This will help you track your equipment’s health and resale value.

Conclusion: Keep Your Machinery Running Smoothly

Regular maintenance is the key to prolonging the life of your farm equipment and ensuring smooth operations. By following a thorough farm equipment maintenance checklist, you can reduce downtime, increase efficiency, and prevent costly repairs. Remember to inspect your machinery regularly, change fluids, clean filters, lubricate moving parts, and store your equipment properly.

If you’re looking for quality farm equipment and expert advice, visit Agri Route at our website www.agri-route.comor stop by our physical location at Office No 13 A, Building-A, 2nd Floor, City Vista, Kharadi, Pune - 411014, Maharashtra (India). You can also reach us at 07620144503. Let us help you maintain your farm machinery and keep your operations running at full capacity!